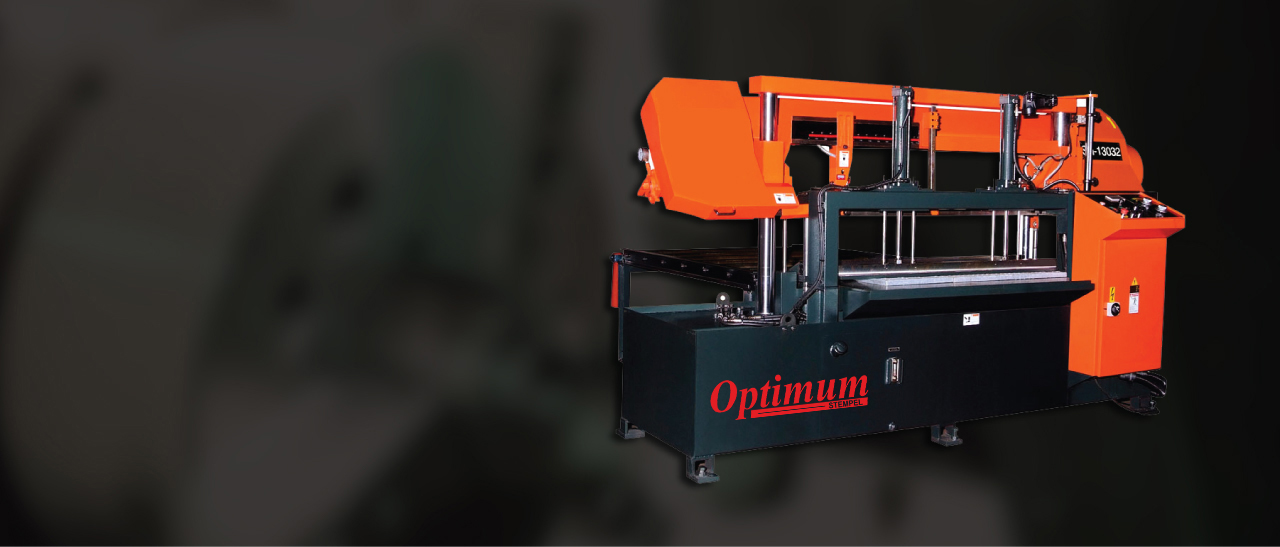

Optimum industry machines incorporate a wealth of experience in fabrication technology coupled with pioneering innovations. They enable you to fabricate parts in any format, from the simplest to the most complex, precisely and cost-effective. Optimum machines are above all renowned for their flexibility, finished part quality, and a high cost-benefit ratio. Moreover, Optimum can meet all of your additional requirements – for tools, automation and software – from a single source.

Company was found and started to manufacture box & pan brake and hand brake machines as well as foot shear.

Added manual slip roll and powered slip roll into production line.

Started to manufacture hydraulic type shearing machines.

Started to manufacture heavy-duty hydraulic double-pinch 3-roll bending machine and hydraulic press brake machine.

Added 2 axes NC control on hydraulic press brake machine.

Added NC back gauge control on hydraulic shearing machine

Started to manufacture Lock forming machine and its optional roll sets.

Started to manufacture hydraulic type box & pan brake machine.

Started to manufacture initial-pinch type roll bending machine.

Purchased new factory property and start to build new factory building.

Move to new factory and increasing employee to total 35 persons.

Installed " heat treatment " facility for wooden case packing material, under " ISPM15 " regulation to issue " PHYTOSANITARY CERTIFICATE " .

Develop europe type hydraulic folding machine and power slitter.

Installing extra two factory building. Total 4 factory building and start to manufacturing 2 axes nc folding machines.

Develop hydraulic notcher HY-4.

Install 3 set of double-column machining center into production line.

Develop Iron worker.

Develop 4-roller rolling machine.